Applications

Take products above and beyond with Origami Composites

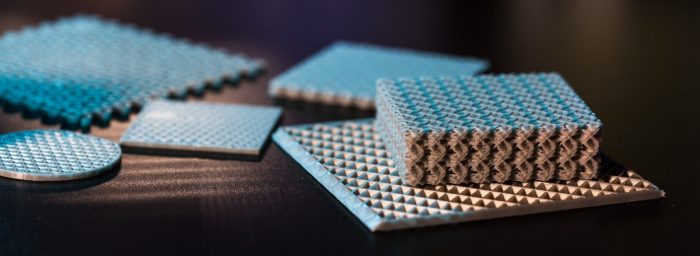

Our technology unlocks advanced functionality that’s difficult or impossible to fabricate with normal materials. Complex geometries are made possible by leveraging the flat-to-folded concepts of origami using accessible, scalable, and well-known manufacturing methods.

Below are some of the advanced functionalities that allows Origami Composites to outperform more common materials.

Lightweighting +

The market is saturated with options for lightweight materials, from fiber-reinforced composites and lattice materials to more traditional foams and honeycomb.

Origami Composites go further. In addition to being lightweight they can be made with commodity resins, scalable manufacturing options, and readily integrated into existing products.

They can also offer exceptional shear strength, something foams and honeycomb can’t touch.

Our flagship product, ArmorONE panels, use the Origami Composite MetaCORE®. It’s ideal for panel applications where lightness and strength are necessary – like semi-trailer or box truck paneling. But there are countless other potential panel applications, like garage doors, wall partitions, or marine components.

Flexibility

Origami Composites can be designed to overcome thermal and mechanical stresses by expanding or softening as required – all while maintaining structural integrity.

A useful application of this flexibility is for Enhanced Geothermal System components, where the harsh and hot conditions deep underground are mitigated by replacing rubber-like parts with a high-temperature thermoplastic origami composite. The lattice geometry designed into the plastic will soften at high temperatures, so it squishes like a rubber and holds pressure like an O-ring, but won’t suffer the same corrosive or thermal damage that rubber will.

Insulation and thermal management

Traditional insulating materials like foams and wools are used in all manner of applications, from building materials to premium coolers. Compared to advanced products like aerogels and vacuum insulated panels (VIPs), they are cheap – but the trade-off is low performance. Aerogels and VIPs may perform better, but they are fragile and costly.

Origami Composites, on the other hand, can be designed with high R-values while being cost effective. They offer substantially better shear strength – the result of being rationally designed rather than randomly formed. Foams fail primarily via shear, so origami composites offer a considerably increased material life span.

Auxetic properties

Normal materials are meiotic, meaning they shrink when pulled and grow when pushed – think modeling clay or a seat cushion. Origami Composites can be designed with mechanical properties that normal materials can’t possess, like being auxetic – growing when pulled and shrinking when pushed.

By physically or mechanically compressing an auxetic Origami Composite into a space, it will shrink. When the pressure is relieved, it will expand to fill the available space and press against the cavity.

The ability to “press-fit” offers benefits to a range of industries, including building construction, where installation of spray foam is unreliable and suffers long-term compressive strength degradation.

Acoustic control

Starting as a flat sheet that has curves or creases built into it, Origami Composites take on a three dimensional shape. This shape can be designed to conform to architectural surfaces, as well as having a texture that promotes acoustic damping or sharpens the sound to meet at a single point – like a whispering gallery or the design of a concert hall.

There is no qualitatively different manufacturing method required to do this kind of shape optimization, only mathematical design that maps the initial flat materials into a final 3D shape, giving Origami Composites the edge in acoustic engineering.

Part consolidation

By the nature of their design, Origami Composites can be used to consolidate system parts, allowing two or more objectives to be performed simultaneously.

A great example of a system that would benefit from part consolidation is electric vehicle battery boxes, where the batteries must be held safely without overheating. Current battery boxes consist of many parts to accomplish this requirement, including an aluminum crash structure and a cooling system – taking up space and time to assemble. An Origami Composite structure could reduce the amount of assembly required, potentially lower the weight, and provide crash protection to the battery while cooling it – all within a single layer.

Contact us today to discuss purchase or licensing options

1-866-778-6415 | sales@armorytechnologies.com