Sustainability

Advanced materials for a better world.

We’re committed to doing better within our own organization and to helping others fulfill their own social and environmental responsibilities.

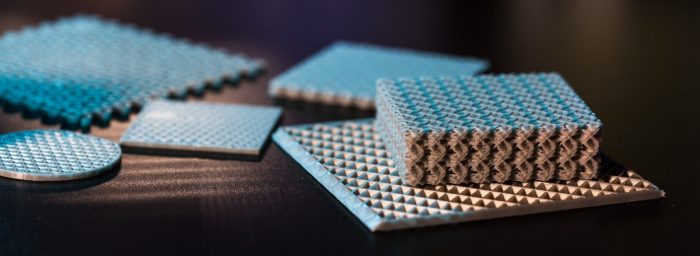

Recycled materials

Our Origami Composite panel cores use 50% recycled materials. 100% of the offcuts produced during thermoforming are reground and reused.

Reduced climate impact

ArmorONE cores are thermoformed, eliminating the need for harmful foam-blowing agents that are used in the production of standard panels.

Greater fuel efficiency

ArmorONE panels are up to 59% lighter, requiring less fuel. It’s a win-win for fleet operators and the environment.

Domestic products

Reduced environmental impact by domestically sourcing all raw materials and manufacturing within the U.S.A.

Reduced CO2

ArmorONE panels contain a lower embodied CO2 compared to standard HDPE foam cores.

Electrification

Lighter panels promote EV trucks by offsetting weight gained through batteries.

Doing more with thermoplastics

Our core material can be made of recycled thermoplastics.

Lowering embodied CO2 emissions

We reduce emissions across the lifespan, from manufacture to end-of-life.

Savings calculator

The lightweighting qualities of ArmorONE panels mean fleets can not only save weight – allowing for more or heavier cargo to be carried – but on fuel costs and CO2 emissions.

What will you do with your savings?

Our foundation is based on our future

Armory is in relentless pursuit of a better tomorrow. Learn more about our dedication to building origami composite solutions.