Products > ArmorONE Panels

ArmorONE® Panels

For walls, doors, ceilings, and floors.

Smarter cores. Better panels.

Improving performance through intelligent design.

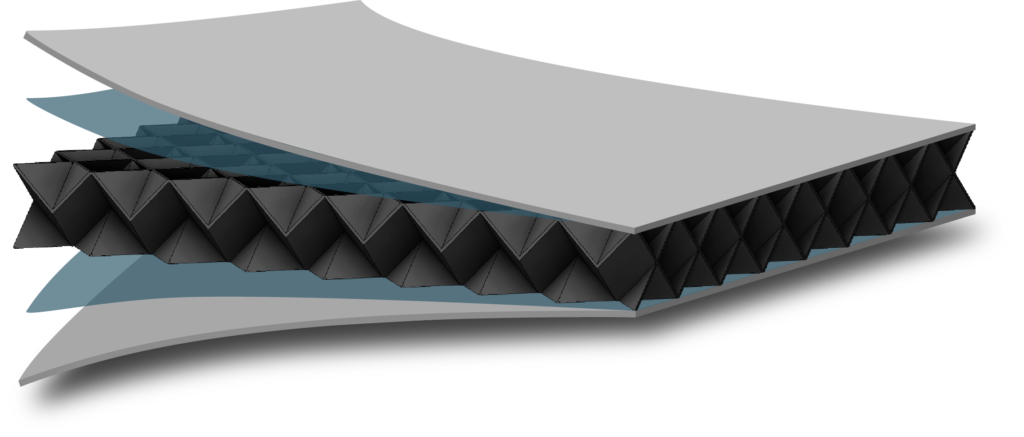

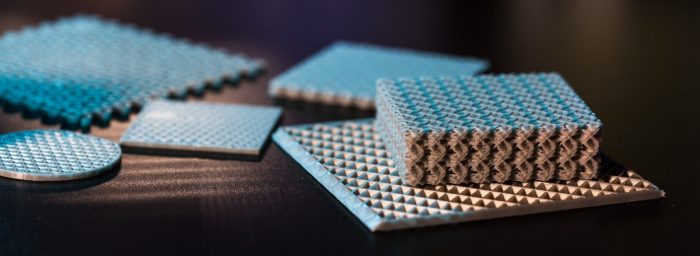

Forget foam and honeycomb. ArmorONE Panels are fabricated with Origami Composites at their core. Developed through R&D with NASA and the National Science Foundation, Origami Composites are engineered with advanced functionality and a higher strength-to-weight ratio than honeycomb or foam. Computationally designed and thermoformed for precision, ArmorONE Panels distribute weight and force to withstand and conform to uncommon stress. They are engineered to meet the unique demands of road transportation.Smarter cores. Better panels.

Improving performance through intelligent design.

Forget blown foam or honeycomb. ArmorONE cores are made with Origami Composites, structured materials designed with advanced functionality that take them above and beyond conventional panels.

Computationally designed and thermoformed for precision, ArmorONE cores were developed through R&D with NASA and the National Science Foundation.

Savings Calculator

ArmorONE panels save weight so fleets can carry more cargo while reducing fuel costs and emissions.

What will you do with your savings?

Improved truck bodies and trailers

With heavier vehicles due to increasing regulation, demand for goods, driver amenities, and electrification – lightweighting is essential for maintaining freight efficiency. ArmorONE can help. Offering unsurpassed weight savings without sacrificing strength or durability, ArmorONE panels can reduce the weight of a truck body or dry van trailer by 800 to 1,800 pounds or more.

The trucking industry has been using the same high-density “plate” technology for decades. Lightweighting initiatives have focused on the chassis and components or costly aluminum parts. Armory Technologies has gone a different route. We’ve designed a low-density advanced composite panel core with enhanced shear strength and stiffness – along with options like better thermal insulation and isotropic impact absorption. Less weight means more freight, and reduced maintenance, operating cost, and emissions.

Watch the video below to see results from the latest trials.

Improved trailers and trucks

With increasingly heavier vehicles due to regulations, driver comfort, increased demand for goods, and electrification – lightweighting is critical. ArmorONE is ideal for semi-trailer and box truck paneling, offering unsurpassed weight savings without sacrificing strength.

Other lightweighting efforts have focused on aerodynamics, a lighter chassis, or even costly aluminum paneling.

Armory Technologies has gone a different route. We’ve redesigned our panel cores to take advantage of geometry to reduce density and provide incredible shear strength – with the possibility of even more advantageous characteristics like better thermal insulation and isotropic impact absorption.

The transportation industry that’s been using the same core technology for decades. ArmorONE is the alternative fleet owners and operators have been searching for.

ArmorONE advantages

Up to 59% lighter than conventional panels.

Choice of colors, finishes, and metal or composite skins.

Superior shear strength and stiffness-to-weight ratio.

Reduced environmental impact with recycled polymers.

Made in the U.S.A. from domestically-sourced materials.

– Steven Grabell, CFO

The data speaks for itself

ArmorONE panels are lighter and stronger than the standard composite panels commonly used to construct semi-trailers today.

Panel weight and strength

No Data Found

No Data Found

No Data Found

Stiffness-to-weight ratio

ArmorONE is stiffer than standard composite panels of the same weight.

| Panel thickness: 7.5 mm | |

| ArmorONE 100 | 6.2 |

| ArmorONE 500 | 4.2 |

| Standard composite | 3.0 |

| Panel thickness: 13.3 mm | |

| ArmorONE 100 | 18.3 |

| ArmorONE 500 | 10.2 |

| Standard composite | 6.7 |

| Other | |

| Steel sheet (4.3 mm) | 1.0 |

| Aluminum sheet (6.0 mm) | 2.1 |

Technology inspired by origami

Learn more about the Origami Composite technology that makes ArmorONE far superior to any composite panel on the market today.